WELCOME TO DANTE'S WORKSHOP

INTRODUCING THE CREW

We are a team of engineers and artists united by our shared passion for films, video games, mechanical design, and, above all, the creation of custom items.

In our philosophy: ‘As you look at an object you can immediately tell that it has a story or not.’

Therefore, a truly authentic look or a function reflective design are the key elements of all our creations.

I’m a mechatronics engineer who loves movies, video games, mechanical things and most importantly: make custom items. In my philosophy: “As You look at an object You can immediately tell that it has a story or not” therefore the true authentic look is the key element for all of my creations.

THE COLLECTIONS

The workshop’s collection includes unique, one-of-a-kind items alongside various limited series products. We are continually engaged in new projects, with the objective of expanding our range to ensure that everyone can find an item they have long desired. We deliver props for diverse purposes, including commercial shoots, film productions, marketing initiatives, prototyping and collection.

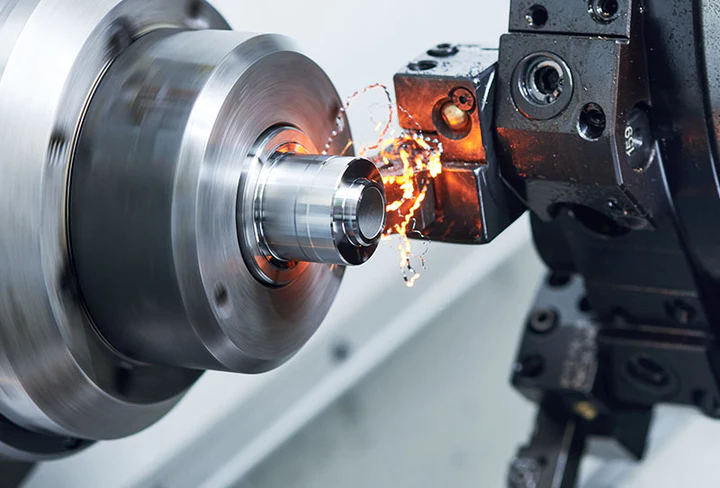

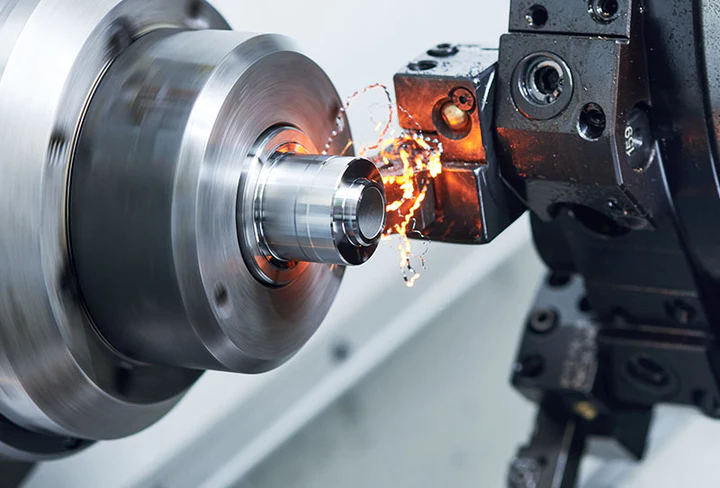

Our European team of dedicated engineers specializes in 3D modeling, with a focus on mechanical and structural design. We bring over seven years of experience in 3D printing and computer controlled machining, and over the past two decades, we mastered every tool both physical and digital, that’s needed for forging ideas into reality. Alongside our highly skilled team of artists and designers we are thrilled to create exceptional products with the most advanced technologies.

TOUGH COMPONENTS

Our favorite materials encompass a diverse range. Almost every piece of our craftsmanship incorporates real metal components, as we believe true authenticity begins with the base material. Whether it is a lightweight alloy, steel, or hardened steel, the combination of genuine metal elements with 3D printed components can significantly enhance the overall aesthetics and durability of an object. Furthermore, various surface treatments, such as anodizing and phosphate coating, offer distinct advantages that are unattainable with non-metal materials.

When it comes to thermoplastics, PLA is often the obvious choice for visual objects and prototypes due to its ease of printing. However, we prefer to work with ABS, Nylon or CF Nylon when a higher level of mechanical strength or increased chemical exposure is required. We are also like to use natural materials such as different types of wood and organic textiles. Finding the appropriate components is crucial for success, and we consistently strive for authenticity in our work.

THE COLLECTIONS

The workshop’s collection contains some unique and unrepeatable items and some other things that come in little series. I constantly keep working on new projects and my ultimate goal is to maintain a greater variety of products where everyone can find a long desired item for themselves.

As a mechatronics engineer, I’m an expert at 3D modeling, especially in mechanical and structural planning. I got more than 80 000 hours of 3D printing experience and over the last 12 years I mastered basically every tool that’s needed for forging ideas to reality. With my immensely skilled team together, we are thrilled to create outstanding products, with the most advanced technologies! From CNC to laser engraving, the possibilities are limitless.

TOUGH COMPONENTS

My favorite components move in a wide range. You can see real metal parts in almost every piece of my crafts and believe me it’s not a coincidence. Working with materials such as ultra lightweight magnesium alloys or steel is unavoidable to achieve exceptional strength and durability. Sometimes I ask myself, even in projects where metal parts are not necessarily needed; what could borrow an even superior, true metallic finish if not real metal elements?

As far as thermoplastics are concerned, PLA is the obvious pick for visual objects and prototypes by its easier printabilities, but I also love to use ABS/Nylon or CF Nylon in some special situations. Although they are much harder to print the end result can endure more heat and chemical impact depending on the chosen filament type. Wood is relatively rare in my lineup but that doesn’t mean I don’t like to work with natural materials. Even my very first creations were made out of plywood with some pine slats and I’ve just recently built a wooden house with my father, but that’s a whole other story…

GET YOUR CUSTOM ORDER TODAY!

We do apply for 100% custom orders where the costumer draws the guideline. With our dedicated engineers and highly skilled artists, we excel in 3D modeling, ranging from mechanical and structural planning to advanced sculpting. Let’s forge your ideas into reality!

We also do apply for 100% custom orders where the costumer draws the guideline. With dedicated engineers and highly skilled artists in our team, we are experts at 3D modeling from mechanical and structural planning to advanced sculpting.

FEATURED PRODUCT CATEGORIES

The journey of an item begins with the raw materials. That’s why we choose only high quality components to achieve excellence.